- HOME

-

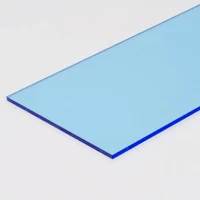

- POLYCARBONATE

- ACRYLIC

-

-

- ACRYLIC SHEETS

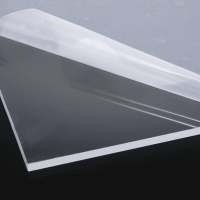

- Clear Acrylic Sheets

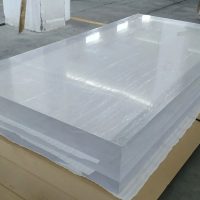

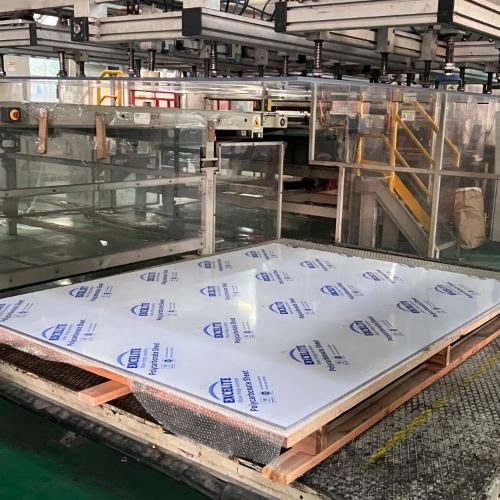

- Cast Acrylic

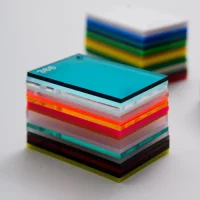

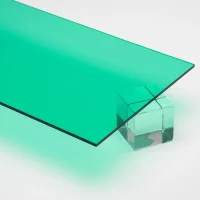

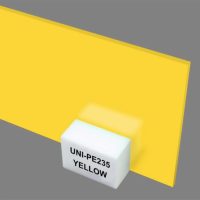

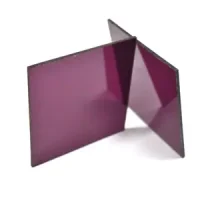

- Tinted Acrylic Sheets

- Anti-Fog Acrylic Sheets

- Acrylic Mirror Sheet

- Translucent Opal Acrylic Sheet

- Anti-Static Acrylic Sheets

- Anti Reflective Acrylic Sheets

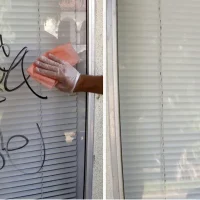

- Anti-Graffiti Acrylic Sheets

- Anti-Glare Acrylic Sheets

- Fluorescent Acrylic Sheet

- Red Acrylic Sheet

- Opal & Matte Acrylic Sheets

- Opal Acrylic Sheet

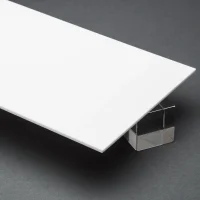

- Matte White Acrylic Sheet

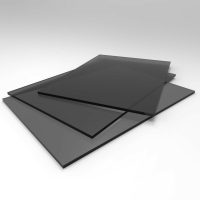

- Matte Black Acrylic Sheet

- ACRYLIC SHEETS

-

-

- FABRICATION

- APPLICATION

- BLOG

- ABOUT US

- CONTACT US