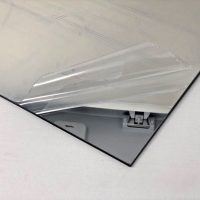

Excelite® polycarbonate mirror sheet and acrylic mirror sheet are a type of non-glass plastic mirror known for its shatterproof and vandal-proof properties, making it highly resistant to damage from high use and abuse. Often referred to as a “soft mirror,” it is available with an optional anti-scratch coating, depending on the specific application.

Compared to traditional glass mirrors, polycarbonate mirror sheets are much lighter and easier to handle, and they can be conveniently cut to size. They provide the same quality reflection as glass mirrors.

These versatile sheets are widely used in creative projects, gyms, aesthetic decoration, and safety areas, offering a safe and practical solution for a variety of environments.